How Diesel and Electric Locomotives Work

Locomotives (popularly called train “engines”) are the heart and soul of the Railway system. Locomotives give life to coaches and wagons which are otherwise dead hunks of metal which can best qualify as shelters during rains, converting them into trains. Locomotives work based on a really simple principle. Be it diesel or electric, locomotives are actually “run” by a set of electric AC induction motors called traction motors attached to their axles. These motors need electric power to run, and the source that supplies this power is what differentiates diesel and electric locomotives. Traction motors are electric motors which are a really bigger, extrapolated, enhanced, more complicated and powerful version of the conventional electric induction motor seen in electric fans, pumpsets etc. The electric power derived from a source is fed to traction motors which run and turn the wheels of the locomotive, the remaining being only details.

In addition to the power output of the engine, many other factors like tractive effort, gear ratios, top speed, weight of the locomotive, axle load, adhesion factors etc also determine the type of service and work the locomotive will be used for, whether for hauling freight, passenger or both (mixed type). This goes for both diesel and electric locomotives. Today’s locomotives are all microprocessor controlled which help them to work efficiently and productively. These computers continuously gather and analyze data to calculate the optimum power required by each axle of the locomotive for its best performance according to the load, grade, speed, adhesion factors etc. They then supply the right amount of power to corresponding traction motors. Supplementing this are all the supporting functions of the loco such as advanced suspension, batteries, Dynamic Brake Resistors, radiators, exhaust and cooling systems, braking and sanding equipment etc.

How Diesel Locomotives Work

A “Diesel Locomotive” is a self-powered railway vehicle that moves along the rails and pulls or pushes a train attached to it using a huge internal combustion engine running on Diesel fuel as the prime mover or the primary supplier of power. However unlike conventional automobiles, modern diesel locomotives have no direct mechanical connection between the engine and the wheels, hence the power generated by the engine does not really “turn the wheels”. The purpose of the diesel engine is not to run the train but to turn a huge electricity generator/alternator which produces electric current (earlier Direct Current, nowadays Alternating Current), then passed through a rectifier to convert the AC to DC if required and is then transmitted to traction motors which then produce the actual (rotational) torque that turns the wheels of the locomotive. Hence, the function of the diesel engine is only to generate power for the traction motors and auxiliary equipment like compressors, blowers etc. Most Indian diesel locomotives have six traction motors, one for each axle except the WDP4 with only four traction motors for six axles. Indian Railways engines have 16 cylinders in V configuration (V16) except for some of the lower powered ones including the WDM2 with only 12 cylinders and the WDG5 which has a V20 engine!

Contrary to popular belief, electric locomotives are much older technology (1881) compared to diesel (1938)! Hence, diesel locomotives work on the same principle as on electric locomotives. It would not be wrong to say that diesel locomotives actually run on electric power, which is why locomotives using this technique of operation are called “Diesel-Electric”, which includes all mainline diesel locomotives in India. In older times there were Diesel-Hydraulic locomotives which had the diesel engine directly driving the wheels through a set of gears like automobiles, but were not only complicated but inefficient and troublesome as well and were replaced by Diesel-Electrics. When we say “transmission” for locomotives, we mean the method or type of electricity transmitted from the engine to the traction motors. Some of the earlier locos had DC (Direct Current) transmission, but all the newer models have AC transmissions and all functions within the locomotive are controlled by computers. The diesel loco is actually quite a sophisticated piece of equipment though does not look it the part. Diesel locomotives are fiercely independent, hugely flexible, can run anywhere and anytime as long as they have enough fuel in their tanks. A generator on wheels that produces its own electricity to run itself!

Diesel Locomotives are basically giant self-propelled electricity generators.

Thanks to IRFCA and Sheeju Chandran

How Electric Locomotives Work

An “Electric Locomotive” is a railway vehicle that can move along rails and push or pull a train attached to it using electric power drawn from an external source, usually from overhead cables or a third rail. Electric Locomotives, be it a standalone unit or the powercars of an EMU trainset, work on the single principle of drawing current from external sources and then after sufficiently “modifying” it feed it to the traction motors which turn the wheels. This “modification” of the electric current is aimed at supplying optimum power to the motors for optimum performance under different conditions and loads, involving a complicated process of conversion, reconversion, smoothing and transformation of the current to varying values of frequency, Voltage, Current etc, using banks of components like transformers, rectifiers/thyristors, inverters, capacitors, compressors and other such paraphernalia, housed within the locomotive body or the “shell”. In fact, it is this process of “modification” or transformation what electric locomotive technology is all about. Electric locomotives do not have a central “Engine” or a prime mover drawing parallels to the diesels, one can say that the traction motors are the actual “engines” of the electric locomotive.

There are actually two ways electric locomotives can be classified: one is as per the type of current they draw from the lines (traction power): DC (Direct Current) or AC (Alternating Current), or as per the type of traction motors they use (drives): Those with Direct Current (DC) traction motors or those with 3-phase Alternating Current (AC) traction motors. Both AC and DC drives can work on both AC and DC traction. The main function of all the equipment housed in locomotives is to convert receiving current to make it optimal to use for traction motors.

How (Drive Control) of Electric Locomotives in India Work

The torque put out by traction motors is directly proportional to the current they receive. For starting the train and for accelerating from low speeds they need to put out more torque hence require more current, and vice versa. The process of controlling this power output to traction motors and thereby the speed of the locomotive is called “controlling the drive” and is carried out completely different for locomotives with AC and DC motors.

DC Drive: Older locomotives in India with DC traction motors used silicon-controlled rectifiers, the current to which and to traction motors was controlled by a device called a tap-changer. Single phase AC received through the Pantograph is passed to the transformer where it is stepped down to manageable levels. It then passes through the tap-changer which according to the input from the driver selects the optimum current required to power the traction motors by “tapping” it from the secondary transformer coil at the appropriate position (Current is different at different points of the winding), which is then passed to the main rectifier (SCR) that converts the AC into DC. After passing through a smoothing reactor to remove fluctuations in the current, it is fed to the traction motors which turn the wheels. In the loco cabin, the loco driver would turn a handle/wheel up and down “notches” 1 to 32 to control the acceleration/speed of the locomotive, where each notch actually specified a point on the winding where the tap-changer would tap current from. Notch 1 is the starting point where maximum power would be drawn as starting up from a standstill requires most torque. As the loco accelerates, lesser torque will be required and accordingly the pilot will move up the notches and at notch 32 the loco will be at the highest speed with the least current output. The tap-changer can be said to be the “throttle” of the electric locomotive.

AC Drive: Three-phase AC locomotives use contactless semiconductor devices like GTO Thyristors (Diodes) or IGBTs (transistors) to control their traction motors. The 25 kV single phase AC current received by the Pantograph will be as usual stepped down by the transformer and passed on to the main GTO Thyristor/IGBT-controlled rectifier which converts it into DC (2800V for WAG9) which passes through a bank of capacitors and inductors where it is smoothed, called a DC-Link. The DC is then sent to the main inverter, again consisting of GTO/IGBTs which will convert the DC into 3-phase AC as required (2180V for WAG9) which is then fed to the motors driving the wheels. During this entire process, the current output to the traction motors will be controlled by varying the output currents/voltages across all components by the Thyristors/IGBTs on command by the microprocessors controlling the locomotive as per instructions from the loco driving cabin. The entire setup is called a VVVF (Variable Voltage Variable Frequency) drive and is seamless and efficient. No more tapping or changing.

In both AC and DC drives, the appropriate output power from the rectifier or inverter is also used to power all the numerous auxiliary equipment in the loco such as blowers, fans, compressors, lights, meters, batteries and so on. And there is a lot more equipment to fine-tune all current at different stages for best use by equipment. AC drives and semiconductor devices are more efficient since they have no moving parts, lighter, generate less heat and are easier to maintain. In India, older DC motor locos like WAM4, WAG5, WAG7 and WAP4 locomotives use tap-changers while 3-phase AC WAP5, WAP7 and WAG9 locos utilize either GTO Thyristors or IGBT drives.

The major drawback of electric locomotives is that they are totally dependent on the power which has to be supplied for it to run. Any power outage, short circuit or breaking of Overhead Equipment (OHE) will cause trains to come to a standstill. Hence, even on fully electrified routes, diesel locomotives are kept on standby always. And on partly electrified routes, trains are run on diesel under the wire because it is more efficient than switching locomotives. However, electrics are always faster and powerful because no diesel engine can generate electricity that can match the power and efficiency of drawing and manipulating electricity directly from the grid.

Electric Locomotives are basically giant electrical transformers on wheels.

Image Courtesy: The Physics of Electric Locomotives

The Diesel vs Electric Question

By around the end of the 1950s when it had become clear that the future did not lie in steam traction and it had to be done away with, the question arose on what technology of locomotive propulsion we should be adopting going forward. The contest between Diesel and Electric traction was fierce, a debate that continues to this day. The major factor in the argument was, of course, the cost. Diesel seemed to be low on tech and speed but was seen as more cost effective even though the fuel had to be imported. Diesels are easy to run and maintain and are very flexible to operate since they don’t have to depend on any external factors to run. Also, diesel entailed no need for any modifications of existing infrastructure. Electric traction was favored to be cleaner, faster, more “modern” and powerful but was voted down because it entailed heavy investments in technology and infrastructure. Lines had to be electrified by creating circuits, planting poles, drawing cables for hundreds of kilometers and establishing tens of substations, all which would run up unimaginable costs in terms of material, labour, and technology, though it would be a one-time activity which could outweigh Diesel costs in the long run. So Diesel won the race initially and it was decided to electrify only the most major trunk routes and suburban lines (HWH-NDLS/CSTM, NDLS-BCT etc), while most other lines would run diesel. But the 1973 oil crisis changed everything. To reduce our reliance on costly imported oil and for more efficient operation, an almost knee-jerk decision was taken to aggressively electrify all major routes at a target of 1000 km a year, starting 1979. This is still going on, though the pace of electrification has slowed down substantially. But still, electric had won.

Electric locomotives are faster, more efficient and powerful compared to Diesel Locomotives which are more flexible to operate. But even then an all-out blanket electrification of all routes in the country is never feasible. Electrification of railway lines come at a huge, huge cost, and it should be carried out only if the gains and savings are substantial in the long run. Diesel prices may be going up, but even then it makes no sense to electrify branch lines which have only six trains passing daily. Electric traction is best suited for high-volume trunk routes like Bombay – Delhi, Kolkata – Kanpur – Delhi, Delhi – Ambala, Chennai – Kolkata, Delhi – Bhopal – Vijayawada – Chennai, Mumbai – Kolkata, suburban commuter lines, lines with high-density long-distance traffic with frequent stoppages like the entire state of Kerala, Coimbatore – Chennai, Mumbai – Ahmedabad, Chennai – Bangalore – Mysore, Mumbai – Pune, UP/Bihar etc. For low volume traffic lines, ghat sections, rainy areas and heavy freight routes, diesels are the best suited because of volumes. As the saying goes, a non-electrified double line is always better than an electrified single line. Indian Railways, fortunately, seems to be headed in this direction which makes sense and hopefully will prevail.

Why Separate Locomotives for Passenger and Freight Traffic? What are “Mixed” Locos?

A doubt many people have is: “Why are there separate locomotives to haul passenger and freight trains? And why another “Mixed” type?” “What is the difference between, say, a WDP4 and WDG4 or a WAP7 and WAG9, since they all have the same engines/traction motors and power?”

The answer is simple. Passenger trains need speed (power) while freight trains need pulling force (torque) which requires locomotives to be designed differently to cater to these two needs. Imagine you starting off an empty car versus a car fully loaded or with a trailer attached. This is the same case in point. Loads that freight locomotives have to pull will be many hundreds of times heavier than that of passenger trains, requiring goods locomotives to have more “Starting Traction” force or torque, adhesion factor (Grip) and overall weight to get all that load moving from standstill, else the wheels will lose grip and just spin on the track, called “Wheel Slip”. This torque, however, comes at the cost of speed, but speed is not important for freights. Passenger locomotives, on the other hand, can be lighter and less torque-y to achieve higher top speeds. For two locomotives with the same power rating, this is achieved majorly by two things: weight of the locomotive and their gearing. Freight locomotives must be heavier and have lower Gear Ratios (traction motor gearing) to make the locomotive to be able to transmit more force to its wheels giving them increased starting torque to pull heavy loads, while passenger locomotives must be lighter and have higher Gear Ratios to achieve higher speeds at low torque. This also makes freight locos capable in hauling passenger trains but we rarely see a passenger loco haul freight trains. Mixed locomotives tread the middle path and try to balance both speed and torque as a compromise, making them good and bad at both. In modern 3-phase locomotives, software for the computers controlling the locomotive also plays a part in deciding what load the loco should handle. All this is applicable for both diesel and electric locomotives.

Let us see how the WDM3A, WDP3A and WDG3A and WAP7 and WAG9 are different from each other.

| Loco Class | Load Type | Power (Hp) | Weight | Axle Load | Tractive Effort | Adhesion Factor | Gear Ratio | Top Speed |

| WDG3A | Goods | 3100 | 123 t | 20.5 t | 37.9 t | 30.80% | 74:18 | 105 kph |

| WDP3A | Passenger | 3100 | 117 t | 19.5 t | 29.25 t | Unknown | 61:22 | 160 kph |

| WDM3A | Mixed | 3100 | 113 t | 18.8 t | 30.4 t | 27% | 65:18 | 120 kph |

| WAP7 | Passenger | 6350 | 123 t | 20.5 t | 36.0 t | Unknown | 72:20 | 140 kph |

| WAG9 | Goods | 6350 | 123 t | 20.5 t | 36.0 t | Unknown | 77:15 | 100 kph |

Indian Locomotive Classes, Types, Statistics and Explanations

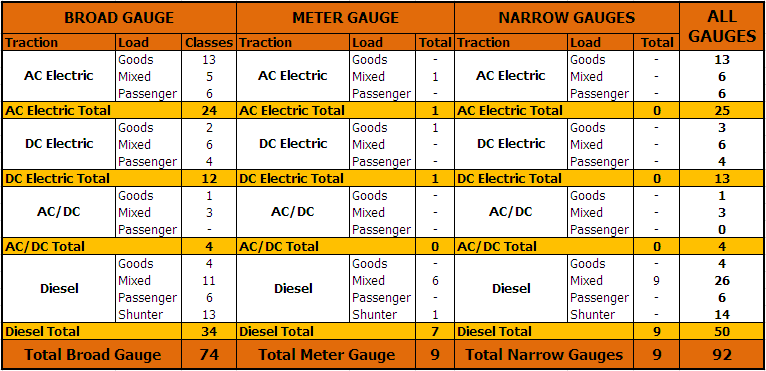

Since its formation in 1948, the Indian Railways has operated 92 different classes of diesel and electric locomotives. Only four types of Steam engines were widely known to be in service, the WP, WG, YG and YP class locomotives, which were all withdrawn from active service by the late 1980s. Today, the scene is dominated by Broad Gauge AC Electric and Diesel Locomotives. Here is a drill down of the classification of these locos in terms of Gauge, Traction, and Load, based on how many are diesel and different types of electric traction. For example, there have been 6 classes of Broad Gauge AC Electric Passenger Locomotives, 11 classes of BG Diesel Mixed locos, 1 class of DC electric Goods loco, total 13 classes of AC electric Goods locos and 9 classes of Meter Gauge locos and 50 types of Diesel locomotives in all and so on. In the next parts, we will check out most of these loco classes one by one, starting with the Diesels.

More Chapters on Indian Locomotives

Locomotives of the Indian Railways | Locomotives Terminologies and Design

How Locomotives are Classified | How Electric and Diesel Locomotives Work

DIESELS: The WDM Series (ALCOs) | The WDP and WDG Series (ALCOs and EMDs)

ELECTRICS: DC and AC/DC Locos | The WAM Series (AC mixed) | The WAG Series (AC Freight)

Excellent info. Thanks for sharing